Simec srl manufactures circular saw cutting machines for tubes and solid bars made of steel and non-ferrous metal alloys specifically studied to last in time and to feature precision mechanics requiring poor maintenance. Each machine can be fine-tuned and modified to meet the various production requirements of the customer.

With long years of expertise, the Simec team of qualified technicians, supported by the company archive, can identify the spare part needed for any machine built up to over 30 years ago in order to either replace or overhaul it. This is possible thanks to the identification codes with which our cutting machines, both standard and custom, are supplied. The company is also ready to collect machines for maintenance and revamping, provided that they are still under warranty, which will only apply to the rendered service.

Quick deliveries

Low machine downtimes

Smooth production

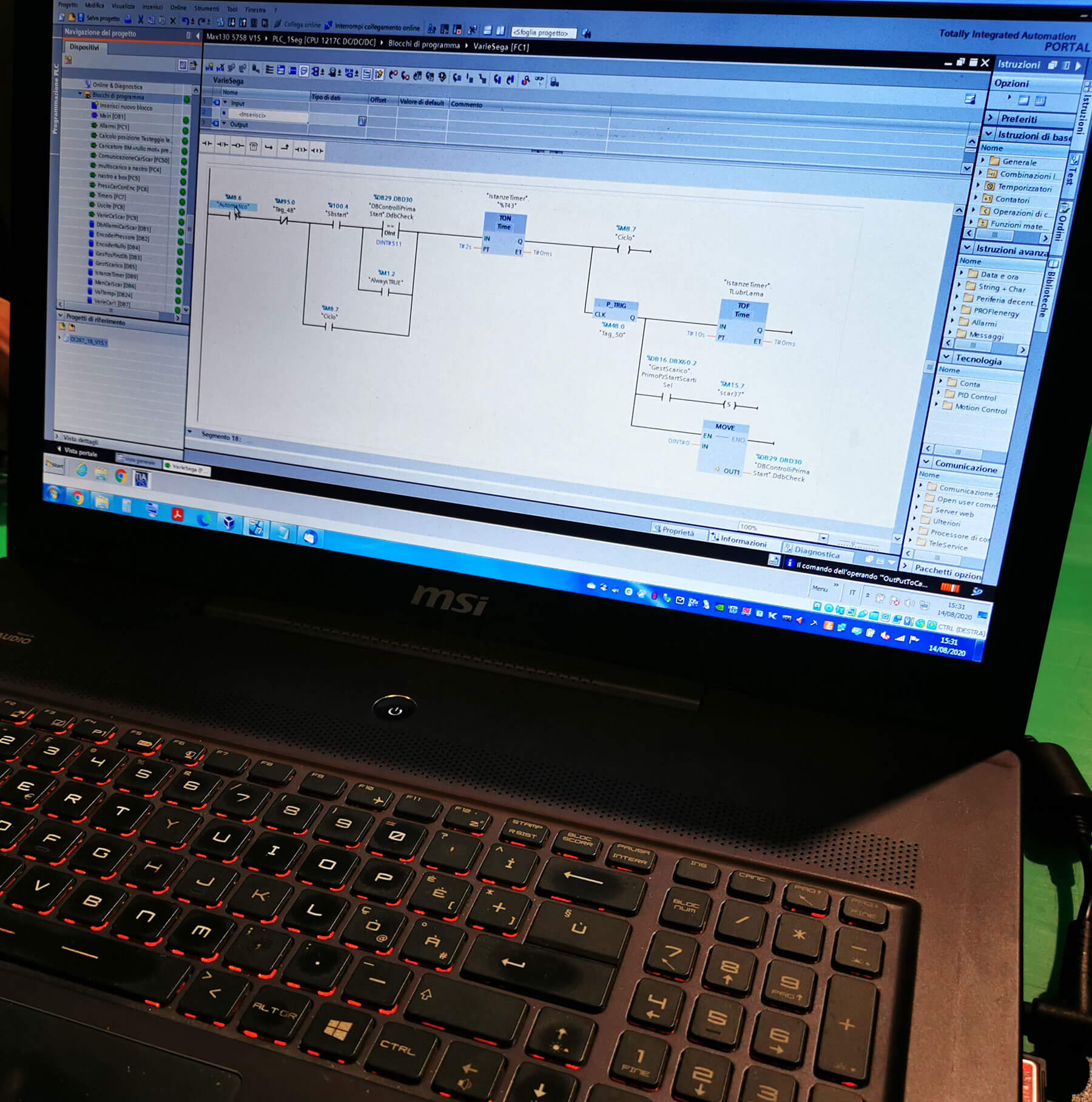

Simec technicians offer customised consultancy and technical support all over Italy and abroad through a local support network in most countries of the world. Machine operation and possible problems can also be checked remotely, which makes support quicker and more effective as it helps prevent machine downtimes or unnecessary movements.

These tools help Simec offer its customers quick services both in Italy and abroad.

Revamp your old machine. Simec can give any circular saw cutting machine for solid bars or tubes a revamping treatment in order to adapt it to Industry 4.0 and to improve its productivity, availing of tax allowances. Greater safety and cutting process optimisation are some of the key targets when overhauling a used cutting machine. The revamping of the old machines makes it possible to safeguard the predefined work processes and to use genuine, just in time spare parts.

Contact our company!